|

LED for lighting of streets, roads and highways

|

|

|

|

|

|

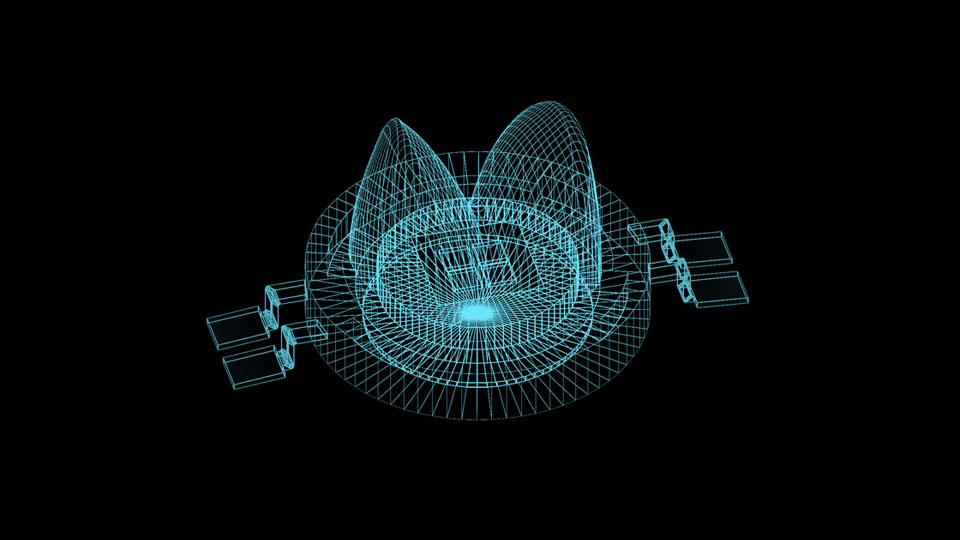

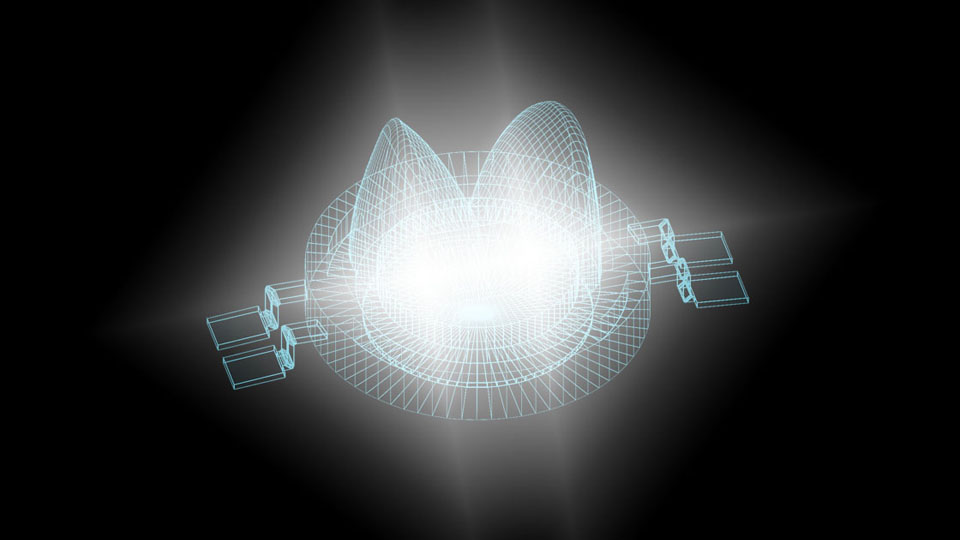

KP2WH-080-2-STREET - the unique KTL LED for street fixtures!

Development of the LED with primary optics (built-in lens) for lighting of highways, streets and roads has been started by KTL engineers in 2009. Around the same time, several well-known in the world manufacturers (OSRAM, Nichia etc.) also tried to equip LEDs with primary optics for achieving a wide diagram of light distribution suitable for street and road lighting. Almost all attempts included disfocusing the light by a small, compared to the size of the crystal, lens, that did not allow designing LEDs which can be complied with the existing standards on light distribution. As a result, manufacturers of fixtures had started to use secondary optics with single (discrete) or group (multi-lens, optical modules) lenses. However, use of secondary optics was connected with numerous shortcomings such as: 1. The costs related to purchasing lenses, associated items, materials and fastening equipment. 2. Use of manual labour which is required for mounting of secondary optics. What in turn not only increase the cost of the fixtures but also delays production terms. And in some cases (in large volumes), execution of order in time is impossible. 3. Fastening for secondary optics is problematic and as a rule is on the horns of a dilemma. Self-tapping screws and silicone gasket seals under lenses should be used that is a higher labour-intensive process and in addition does not provide required tightness of a LED module. Or special glue (i.e. based on silicone or polymer resins) should be used. However, glue in addition to good adhesion to sealable surfaces should maintain high elasticity in wide temperature range. Besides, at incomplete chemical compatibility, some glues can interact with silicone of primary optics of LEDs and other electronic components resulting in failure. 4. Lowering of fixture reliability related to internal mechanical stress of a LED module due to unequal thermal expansion of aluminum basis with installed LEDs and secondary optics. Operating temperature range can exceed 100°C during daily operating cycle of a LED fixture. This leads with time to deterioration of optical characteristics, appearance of cracks or lack of tightness of a LED module. 5. Deterioration of temperature regime of LEDs and consequently - decrease in emission and lowering useful service life. 6. Light losses in secondary optics can reach 20% of luminous flux emitted by LEDs. With time during temperature cycle, light losses can be significantly increased.  Two-chip LED KP2WH-080-2-STREET for lighting of highways, streets and roads in comply with the existing standards and norms In view of the above circumstances, manufacturers of LED street fixtures were forced to apply various tricks for cheapening and simplifying assembly process and reducing optical losses. In practice, group lenses are increasingly using, with fixing by means of filling a light emitting module by elastic compound. Automated equipment for glue applying was offered in the market. But such optimization led to very unpleasant consequences. Firstly, street optics with no protective plafond quickly gets dirty (as any protective glass). However, cleaning of it as it is needed maintaining the initial directional diagram is very problematic. The fixture rapidly loses its main properties and should be dismantled. Secondly, use of group optics initially defines a flat shape and potential dimensions of the fixture. But it is a flate shape that makes it very difficult to develop the fixture fully in comply with the present norms. Designing of complicated lighting devices requires other approaches. These approaches were developed by KTL engineers, namely:

|

|